Precision Coating Co., Inc. (Precision Coating) is ISO 14001:2015 Certified

ISO 14001 – Precision Coating Environmental Policy

Precision Coating is committed to protecting the local and global environment of the Earth. To minimize environmental impacts concerning our activities, products, and services, we pledge to:

- Environmental Management: Establish and maintain an effective Environmental Management System (EMS) to identify, evaluate, and mitigate environmental risks. Set measurable environmental objectives and target metrics to drive visibility and continuous improvement in environmental performance.

- Compliance: Comply with all applicable environmental laws, regulations, and standards and maintain positive relationships with relevant regulatory bodies.

- Pollution Prevention: Minimize waste generation, emissions, and discharges through the adoption of cleaner and more efficient production technologies, processes, and chemistries. Promote resource conservation and efficiency in our operations, including energy, water, and raw materials.

- Emergency Preparedness and Response: Develop and implement emergency response plans to effectively address and mitigate environmental incidents or emergencies. Conduct regular drills and exercises to ensure readiness and enhance response capabilities.

- Product Stewardship: Develop and offer products and services that are safe, environmentally friendly, and meet the highest quality standards. Provide customers with information and support to ensure the safe handling, use, and disposal of our products.

- Sustainable Supply Chain: Collaborate with suppliers to promote sustainable practices and ethical sourcing throughout the supply chain. Identify, evaluate and prioritize suppliers based on their environmental performance and commitment to sustainability.

- Stakeholder Engagement: Engage with stakeholders, including employees, suppliers, customers, regulators, and the community, to foster transparency, collaboration, and mutual understanding on environmental matters.

- Training and Awareness: Provide comprehensive training and resources to employees to raise awareness of environmental issues and promote environmentally responsible behavior. Encourage employee participation and involvement in environmental initiatives and improvement efforts.

- Continuous Improvement: Periodically review and evaluate the effectiveness of our environmental policies, programs, and initiatives. Take prompt corrective actions to address deficiencies and seize opportunities for improvement.

- Reporting and Communication: Regularly communicate our environmental performance, objectives, and progress to stakeholders through transparent and accessible channels. Maintain open dialogue with regulatory authorities, industry partners, and other stakeholders to share knowledge and best practices.

The Company is committed to environmental stewardship, sustainability, and corporate responsibility. This Policy will be communicated to all employees, contractors, and suppliers, and be available to the public through selected media.

Precision Coating está comprometido a proteger el medio ambiente local y global de la Tierra. Para minimizar los impactos ambientales relacionados con nuestras actividades, productos y servicios, nos comprometemos a:

- Gestión Ambiental: Establecer y mantener un Sistema de Gestión Ambiental (SGA) eficaz para identificar, evaluar y mitigar los riesgos ambientales. Establezca objetivos ambientales mensurables y métricas objetivo para impulsar la visibilidad y la mejora continua en el desempeño ambiental.

- Cumplimiento: Cumplir con todas las leyes, regulaciones y estándares ambientales aplicables y mantener relaciones positivas con los organismos reguladores pertinentes.

- Prevención de la contaminación: Minimizar la generación, emisiones y vertidos de residuos mediante la adopción de tecnologías, procesos y productos químicos de producción más limpios y eficientes. Promover la conservación y eficiencia de los recursos en nuestras operaciones, incluyendo energía, agua y materias primas.

- Preparación y respuesta a emergencias: Desarrollar e implementar planes de respuesta a emergencias para abordar y mitigar eficazmente incidentes o emergencias ambientales. Realice simulacros y ejercicios periódicos para garantizar la preparación y mejorar las capacidades de respuesta.

- Administración de productos: Desarrollar y ofrecer productos y servicios que sean seguros, amigables con el medio ambiente y cumplan con los más altos estándares de calidad. Proporcionar a los clientes información y soporte para garantizar el manejo, uso y eliminación seguros de nuestros productos.

- Cadena de suministro sostenible: Colaborar con proveedores para promover prácticas sostenibles y abastecimiento ético en toda la cadena de suministro. Identificar, evaluar y priorizar proveedores en función de su desempeño ambiental y compromiso con la sostenibilidad.

- Participación de Partes Interesadas: Interactuar con las partes interesadas, incluidos empleados, proveedores, clientes, reguladores y la comunidad, para fomentar la transparencia, la colaboración y el entendimiento mutuo en cuestiones ambientales.

- Entrenamiento y Concientización: Proporcionar formación integral y recursos a los empleados para crear conciencia sobre cuestiones ambientales y promover un comportamiento ambientalmente responsable. Fomentar la participación y la implicación de los empleados en iniciativas medioambientales y esfuerzos de mejora.

- Mejora continua: Revisar y evaluar periódicamente la efectividad de nuestras políticas, programas e iniciativas ambientales. Tomar acciones correctivas inmediatas para abordar las deficiencias y aprovechar las oportunidades de mejora.

- Informes y Comunicación: Comunicar periódicamente nuestro desempeño, objetivos y avances ambientales a las partes interesadas a través de canales transparentes y accesibles. Mantener un diálogo abierto con las autoridades reguladoras, socios de la industria y otras partes interesadas para compartir conocimientos y mejores prácticas.

La Compañía está comprometida con la gestión ambiental, la sostenibilidad y la responsabilidad corporativa. Esta Política se comunicará a todos los empleados, contratistas y proveedores, y estará disponible al público a través de medios de seleccionados.

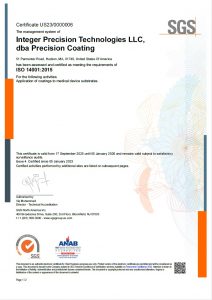

Precision Coating Co., Inc. (Precision Coating), N2 Biomedical, and Providence Texture are ISO-13485-2016 Certified

Precision Coating is committed to the highest quality customer and product service.

We hold certificates of registration for ISO 13485:2016. These certifications ensure Precision Coating’s ongoing commitment to continual improvement, customer satisfaction, and sustainability in medical applications, military applications, and commercial applications.

ISO 50001:2018 – Commitment to Sustainable Energy Management

At Precision Coating, we are dedicated to enhancing our energy management and consumption practices. We proudly hold ISO 50001:2018 certification in our Costa Rica facility, a testament to our commitment to continuous improvement in energy efficiency. This certification not only highlights our dedication to sustainable practices but also reinforces our role in advancing environmental responsibility for the future.

Política del Sistema de Gestión de la Energía (Spanish)

Precision Coating S.R.L, en cumplimiento de su misión y objetivos estratégicos, es consciente de que el uso eficiente de los recursos energéticos es un pilar fundamental para ser competitivos y ambientalmente sostenibles.

Para ello, Precision Coating S.R.L ha establecido metas energéticas en sus operaciones, como parte de un Sistema de Gestión de la Energía (SGEn) modelado en el estándar ISO 50001:2018, con el fin de lograr la mejora continua del desempeño energético, en el uso y consumo de la energía y la eficiencia energética.

Precision Coating S.R.L mejorará continuamente su desempeño energético adquiriendo los siguientes objetivos:

- Apoyar la compra de productos y servicios eficientes en energía con el fin de mejorar el desempeño energético.

- Asegurar la disponibilidad de información y recursos para lograr los objetivos y metas energéticas.

- Cumplir con los requisitos legales aplicables y otros requisitos relacionados con sus usos y consumos energéticos, así como la eficiencia energética.

- Fomentar el uso eficiente de la energía y el ahorro energético en sus instalaciones, para fuentes de consumo térmico y eléctrico.

- Implementar nuevas tecnologías y mejorar las existentes para consumir energía en las instalaciones de manera más eficiente.

- Mejorar la cultura interna, las prácticas y los hábitos de consumo de energía por parte de los colaboradores y personal de nuestros contratistas.

- Apoyar las actividades de diseño que consideren la mejora del desempeño energético.

- Mejorar continuamente el desempeño energético y el SGEn

Energy Management System Policy (English)

Precision Coating S.R.L., in compliance with its mission and strategic objectives, is aware that the efficient use of energy resources is a fundamental pillar to be competitive and environmentally sustainable.

To this end, Precision Coating S.R.L. has established energy goals in its operations, as part of an Energy Management System (EnMS) modeled on the ISO 50001:2018 standard, to achieve continuous improvement in energy performance, energy use and consumption and energy efficiency.

Precision Coating S.R.L. will continuously improve its energy performance by acquiring the following objectives:

- Supports the purchase of energy-efficient products and services to improve energy performance.

- Ensures the availability of information and resources to achieve energy objectives and goals.

- Complies with applicable legal requirements and other requirements related to their energy uses and consumption, as well as energy efficiency.

- Promotes the efficient use of energy and energy savings in its facilities, for thermal and electricity consumption sources.

- Implement new technologies and improve existing ones to consume energy in facilities more efficiently.

- Improves the internal culture, practices and energy consumption habits of our contractors’ employees and personnel.

- Supports design activities that consider improving energy performance.

- Continuously improves energy performance and EnMS.

FDA approves Precision Coating’s MICRALOX® for use in repeat-use food processing

The U.S. Food and Drug Administration (FDA), Center for Food Safety & Applied Nutrition recently approved the use of specially sealed anodized aluminum, MICRALOX®, a proprietary hard coat product made by Precision Coating, to be suitable for food contact. The hard anodic coating will serve as the food contact surface of parts of repeat-use food processing equipment, such as molding equipment and extruders.

MIL-STD-171

MIL-STD-171 is the military standard that established the minimum requirements for finishing, and otherwise treating, metal and wood surfaces, and to serve as a general guide to the selection of suitable finishing materials, procedures, and systems.

As the MIL-STD-171 standard pertains to aluminum parts and finishes provided by Precision Coating

- MIL-STD-171, 7.2.1 calls out Anodic film on aluminum, sulfuric acid, MIL-A-8625*, Type II Class 1, nondyed

- MIL-STD-171, 7.2.2 calls out Anodic film on aluminum, sulfuric acid, MIL-A-8625,* Type II Class 2, dyed, color to be specified

- MIL-STD-171, 7.3.1 calls out Chemical film, chromate, MIL-C-5541 Class 1A, for maximum protection against corrosion, painted or unpainted

- MIL-STD-171, 7.3.3 calls out Chemical film, chromate, MIL-C-5541 Class 3, for protection against corrosion where low electrical resistance is required

- MIL-STD-171, 75.1 calls out Hard anodic coating on aluminum, MIL-A-8625*, Type III, Class 1 – thickness 0.002” ± 0.0002” unless otherwise specified, nondyed

- MIL-STD-171, 7.5.2 calls out Hard anodic coating on aluminum, MIL-A-8625*, Type III, Class 2 – thickness 0.002” ± 0.0002” unless otherwise specified, dyed, color to be specified.

Sanford Hard Coat

(Hard Anodize Natural and Colors)

- MIL-A-8625, Type III, Class1 AMS 2468

- MIL-A-8625, Type III, Class2 AMS 2469

- AMS-A-8625, Type III, Class1 BAC 5821

- AMS-A-8625, Type III, Class2 PS 13208

- MIL-STD 171, 7.5.1 PS 13201

- MIL-STD 171, 7.5.2 PS 13201.1

- HP 4-79

Sanford HARDLUBE® (Hard Coat w/Teflon®)

- MIL-A-63576, Type I AMS 2482

- Sulfuric Anodize ( Clear and Colors)

- MIL-A-8625 Type II, Class 1 AMS 2471

- MIL-A-8625 Type II, Class 2 AMS 2472

- AMS-A-8625, Type II, Class1 DPS-11.05

- AMS-A-8625, Type II, Class2 DPS-11.06

- MIL-STD-171, 7.2.1

- MIL-STD-171, 7.2.2

Clear and Color Anodizing to Aluminum Association (AA) & American Architectural Manufacturers Association (AAMA) finish designations

Chemical Conversion Coating (Alodine, Iridite, Chem Film)

- MIL-C-5541E, Class 1A, Class 3

- MIL-STD-171

- AMS 2473

- AMS 2474

MIL-A-8625 Aluminum Anodic Coatings

MIL-A-8625 is the military specification for anodic coatings for aluminum and aluminum alloys. This mil-spec covers the requirements for electrochemically-formed anodic coatings on aluminum and aluminum alloys for non-architectural applications. It provides details, methods, and procedures for these various coatings. MIL-A-8625 is approved for use by all Departments and Agencies of the Department of Defense.

Precision Coating’s MIL-A-8625 Anodized Aluminum Finishing

If you need to give an aluminum surface the hardness of case-hardened steel while maintaining the light-weight of aluminum, make Precision Coating your number one choice. Our custom finishes will make your surface sapphire-hard and corrosion- and abrasion-resistant, help it conduct or resist heat, give it lubricity and dielectric properties, and can even color it.

We make extensive use of the Sanford Process®, a proprietary, hard anodizing method so versatile that it enables us to hard coat virtually any alloy—including 2000 series and cast—to meet your particular requirements.

Precision Coating offers the following anodic coating types and classes:

The anodic coating types and classes that Precision Coating offers are as follows:

- MIL-A-8625, Type II, Class 1 – Sulfuric acid anodizing. Conventional coatings produced from a sulfuric acid bath. Non-dyed.

- MIL-A-8625, Type II, Class 2 – Sulfuric acid anodizing. Conventional coatings produced from a sulfuric acid bath. Dyed.

- MIL-A-8625, Type III, Class 1 – Hard anodic coatings. Non-dyed.

- MIL-A-8625, Type III, Class 2 – Hard anodic coatings. Dyed.

(Hard Anodize – Natural & Colors)

- MIL-A-8625, Type III, Class 1 AMS 2468

- MIL-A-8625, Type III, Class 2 AMS 2469

- AMS-A-8625, Type III, Class 1 BAC 5821

- AMS-A-8625, Type III, Class 2 PS 13208

- MIL-STD 171, 7.5.1 PS 13201

- MIL-STD 171, 7.5.2 PS 13201.1

- HP 4-79

(Hard Coat with Teflon®)

- MIL-A-63576, Type I

- AMS 2482

- MIL-A-8625 Type II, Class 1 AMS 2471

- MIL-A-8625 Type II, Class 2 AMS 2472

- AMS-A-8625, Type III, Class 1 DPS-11.05

- AMS-A-8625, Type III, Class 2 DPS-11.06

- MIL-STD-171, 7.2.1

- MIL-STD-171, 7.2.2