Important Distinctions for Achieving Desired Outcomes when Color Anodizing

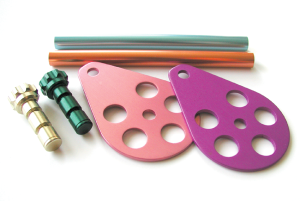

Aluminum anodizing, whether it is type II or type III, is achieved by electro-chemical methods prescribed and designed to yield oxide coatings with certain properties. These properties can be hardness, thickness, electrical resistance, corrosion resistance, bond-ability, lubricity, and/or combinations of several of the above. One common, desirable output of aluminum anodizing is the ability to obtain color on the part—for both type II or type III. When anodizing colors, there is a distinction between color range versus color match. Let’s explore the variables that are behind this. Read more ›

There’s much to consider when designing your aluminum parts to be anodized. If your parts require it, masking can be a crucial step in the process to ensure they are finished in accordance with the engineering specifications. We sat down with Bobby Scott who joined the precursor to DCHN in 1967 to share his knowledge and experience over thousands and thousands of jobs over these many years. An expert in our masking department, he knows the anodizing and masking

There’s much to consider when designing your aluminum parts to be anodized. If your parts require it, masking can be a crucial step in the process to ensure they are finished in accordance with the engineering specifications. We sat down with Bobby Scott who joined the precursor to DCHN in 1967 to share his knowledge and experience over thousands and thousands of jobs over these many years. An expert in our masking department, he knows the anodizing and masking